What's that, a Microlab?

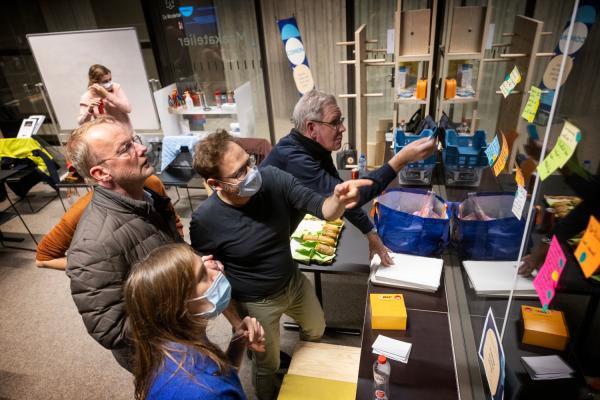

Comon is all about experimenting and bringing people together. That’s precisely what happens during Microlabs. In these labs, diverse teams of inventors work on shaping and testing innovative ideas into functioning prototypes. Discover how a Microlab works and meet all the prototypes developed there.

Video: Miniproeftuin 'UrbanCubby' tijdens het Comon-traject 'Plezierig Bewegen'

Results: which prototypes have already been developed?

- Revonc: an app for exercising together after cancer

- UrbanCubby: smart lockers full of sports and games equipment around the city

- Dolox: a smart watch to log your pain

- RingMe: a phone bot for non-native speakers to prepare your doctor's visit

- ExplainMed, an app that converts your medical report into an understandable explanation

- MIA, a web tool to find customized psychological counseling

From witty idea to experiment

During a Microlab, a diverse team of inventors sets to work to further shape, test and implement an idea into a real working prototype. Comon organizes a 5-day Design Sprint, during which the team immerses itself in the wonderful world of design thinking, prototyping and testing. During test moments, the team has its prototype tested by citizens in order to adjust it with their valuable feedback.

The more diverse the team, the richer the solution

In the name of “The more diverse the team, the richer the solution”, Comon brings people together in a Microlab. It is precisely through a mix of backgrounds and visions that you achieve valuable innovation. That's our belief.

A Microlab team consists of people or organizations from different disciplines: for example a collaboration between a company, a research institution, a civic organization and a local government. Each team also involves Ghentians in the testing phase: users for whom the prototype is intended.

Experiment

One of Comon's goals is to experiment: try, sometimes fail and sometimes adjust. And that is allowed. More so, it is important during an innovation process. You don't innovate overnight. It's a process. Almost every innovation process is composed of the same building blocks: the chemistry between different profiles in a group, an occasional bump in the road with a rollercoaster of emotions associated with it, pulling yourself up with a new idea, going for it, involving your target group and above all: to dare.

A real working protoype

With a budget of 12,000 euros, each prototype is actually made into a real working prototype after the Design Sprint. For example, through a collaboration with a software developer, a makerspace where a hardware prototype is made, or an audiovisual partner.